Welcome to Nibble, Where Craft Meets Cocoa

FOR THOSE WHO JUST LOVE A LOT OF CHOCOLATE IN THEIR CHOCOLATE

What Sets Us Apart

From Cacao Seeds to the Sweetness of Chocolate

While many chocolatiers use pre-made chocolate, we embrace the artistry of crafting chocolate from scratch. Our unique process allows us to infuse our creations with the care and attention that can only come from hands-on craftsmanship.

Our Process

Collapsible content

Sourcing Premium Cacao

We start with the finest cacao beans, carefully sourced to ensure quality and sustainability. Our commitment to premium ingredients sets the foundation for the exceptional taste of our chocolates.

Roasting, Winnowing, and Grinding

The journey from bean to bar involves expert roasting, meticulous winnowing, and precise grinding. This step-by-step process is where the rich flavors and aromas of the cacao come to life.

Refining with Sugar

We combine our finely ground cocoa with just the right amount of sugar. This marriage of ingredients creates a harmonious blend that forms the basis of our delicious chocolate.

Tempering and Packaging

Our dedication to perfection extends to the tempering process, ensuring a smooth and glossy finish. Once tempered, each piece is individually packaged, preserving its freshness and flavor until it reaches you.

At Nibble, we pride ourselves on crafting chocolate with a passion for quality that begins at the source. We take a hands-on approach from the very beginning.

TRUFFLES CHOCOLATE

Crafted with Love, From Bean to Bonbon: Indulge in Vegan & Organic Truffles

Each delectable bite is crafted with love and care, ensuring a divine taste sensation in every flavor. From the bold richness of dark chocolate to the fruity tang of raspberry and the aromatic allure of coffee, our truffles offer a symphony of flavors to tantalize your taste buds. Delight in the pure essence of passion fruit sea salt, the comforting notes of oat vanilla, the spicy warmth of chai, the fiery kick of Mexican, and the refreshing zest of lemon. Savor the essence of true craftsmanship with each heavenly bite.

Total Truffles: 8

+ Certified Organic

+ Whole Unrefined Cane Sugar

+ Vegan

+ Soy Free

+ Gluten Free

+ Paleo

CHOCOLATE FLIGHT

four-bar FLIGHT — a tasteful touch for the perfect chocolate gift.

Unwrap the world of chocolate with our Four-Origin Dark Chocolate Bars, featuring cacao beans sourced from Brazil, Dominican Republic, Madagascar, and Peru.

Each bar weight: 2oz (57g)

Bar size: 3" x 3" x 0.5" (Inches)

Total Nibbles: 9

Nibble size: 0.9" x 0.9" x 0.5" (Inches).

Four bar total weight: 8oz (227g)

+ Certified Organic

+ Whole Unrefined Cane Sugar

+ Vegan

+ Soy Free

+ Gluten Free

+ Paleo

-

Four Bar Flight Gift 72% Cocoa | Chocolate Box | Nibble Chocolate

Regular price $24.00Regular priceUnit price / per -

Four Bar Flight Gift 85% Cocoa | Chocolate Box | Nibble Chocolate

Regular price $24.00Regular priceUnit price / per

NIBBLELITOS

Small Bites, Big Delights

Indulge in our Nibblelitos, bite-sized delights meticulously crafted to perfection. Each jar contains 180 morsels of pure bliss, weighing 6.5oz (180g). Packaged in a sleek glass jar with a sustainable bamboo lid, it's a treat for your taste buds and the environment.

Jar weight: 6.5oz (180g)

Nibblelitos size: 0.4" x 0.4" x 0.4" (Inches)

Total Nibblelitos: 180

Jar type: Glass jar with bamboo lid

+ Certified Organic

+ Whole Unrefined Cane Sugar

+ Vegan

+ Soy Free

+ Gluten Free

+ Paleo

-

Brazil | 72% Cocoa 180 Nibblelitos

Regular price $24.00Regular priceUnit price / per -

Dominican Republic | 72% Cocoa 180 Nibblelitos

Regular price $24.00Regular priceUnit price / per -

Madagascar | 72% Cocoa 180 Nibblelitos

Regular price $24.00Regular priceUnit price / per -

Peru | 72% Cocoa 180 Nibblelitos

Regular price $24.00Regular priceUnit price / per

CHOCOLATE-COVERED

Nourish Your Senses: Chocolate-Coated Wellness, Handcrafted with Care.

Savor our artisanal chocolate-covered nuts or coffee beans, crafted in small batches with just two ingredients: single origin chocolate and a delicate touch of natural flowers. Each bite is a testament to our commitment to quality and flavor.

+ Whole Unrefined Cane Sugar

+ Vegan

+ Soy Free

+ Gluten Free

+ Paleo

-

Chocolate-Covered Almonds Strawberry | Nibble Chocolate

Regular price $13.00Regular priceUnit price / per -

Chocolate-Covered Cashews Chili Mango | Nibble Chocolate

Regular price $13.00Regular priceUnit price / per -

Chocolate-Covered Peanuts Pineapple | Nibble Chocolate

Regular price $13.00Regular priceUnit price / per -

Chocolate-Covered Coffee Beans Butterfly & Lavender | Nibble Chocolate

Regular price $13.00Regular priceUnit price / per

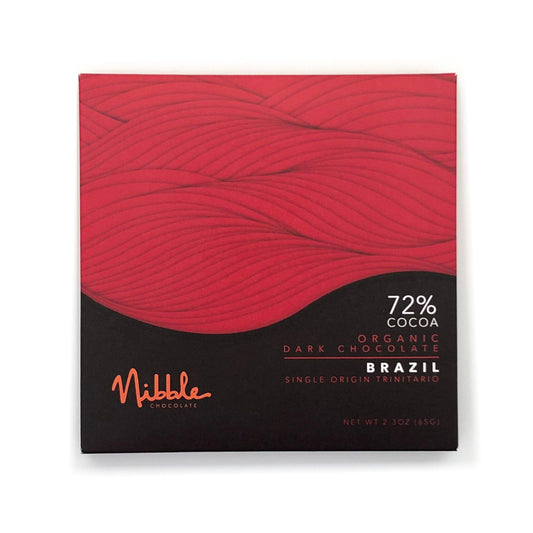

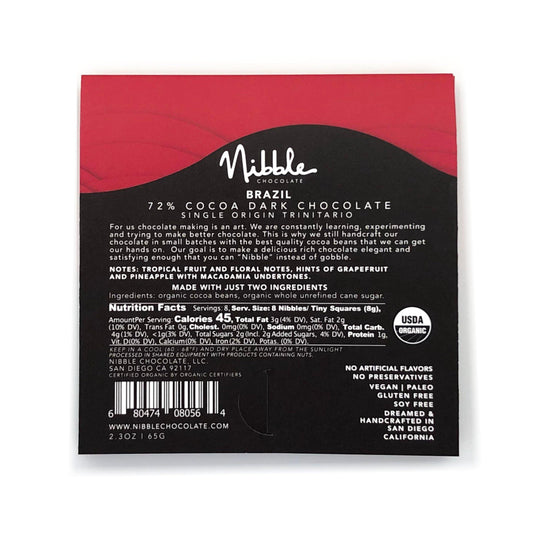

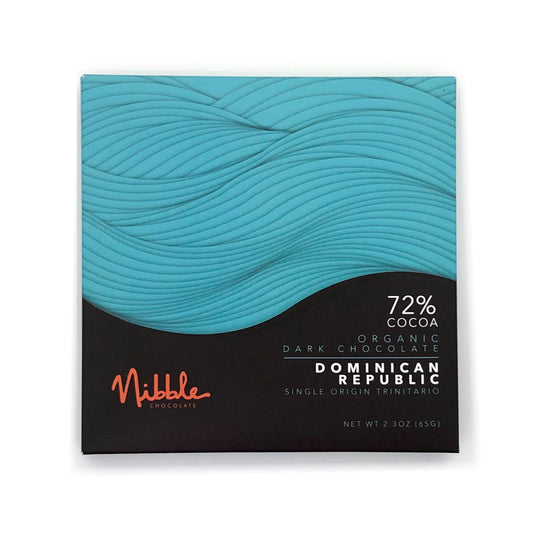

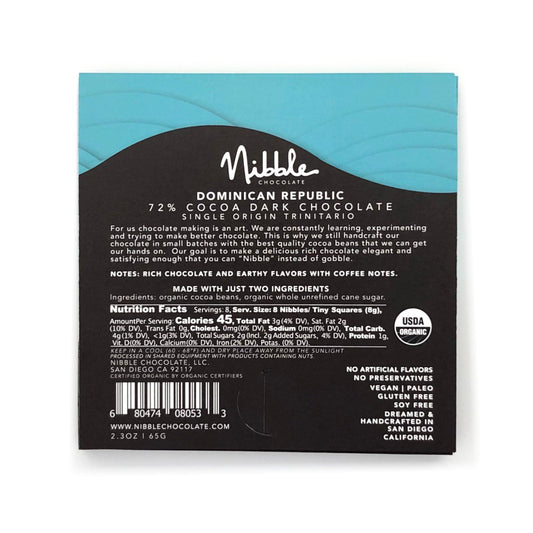

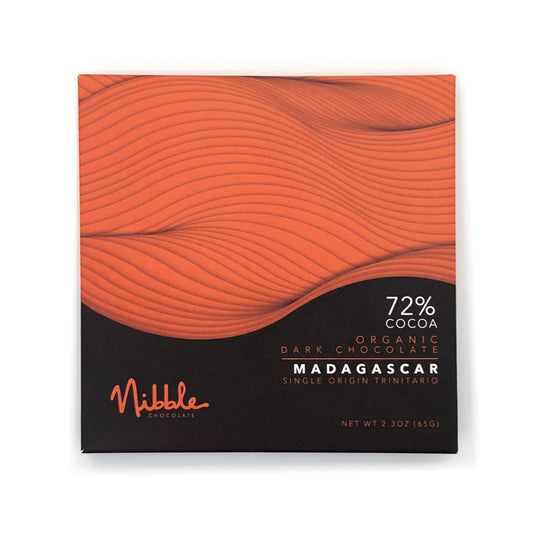

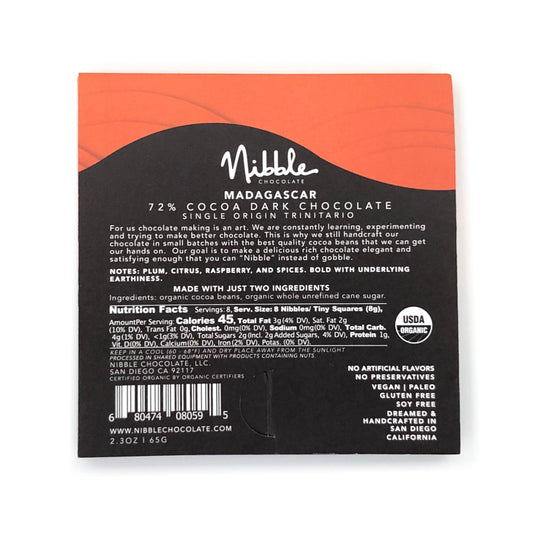

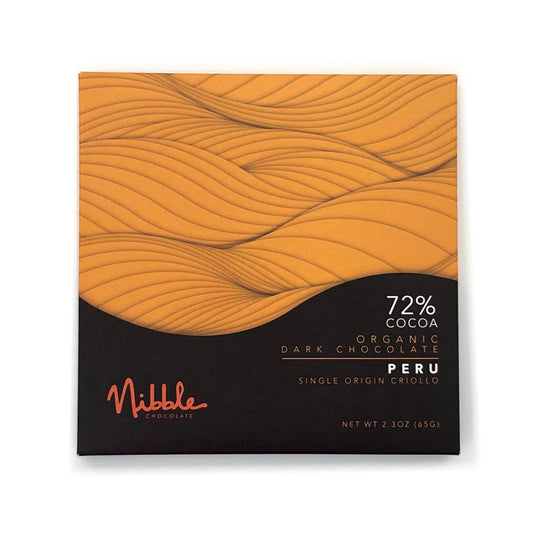

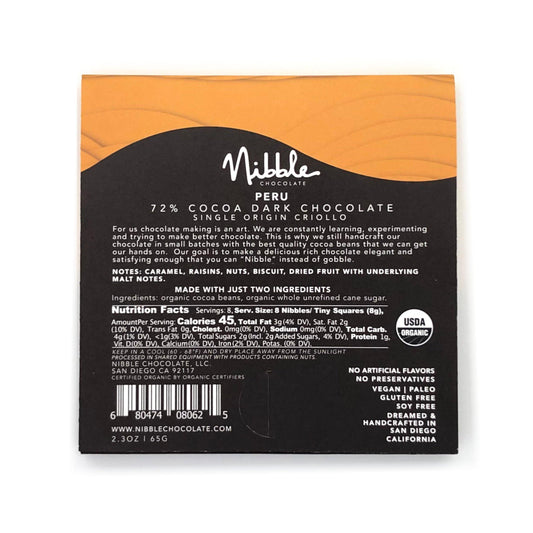

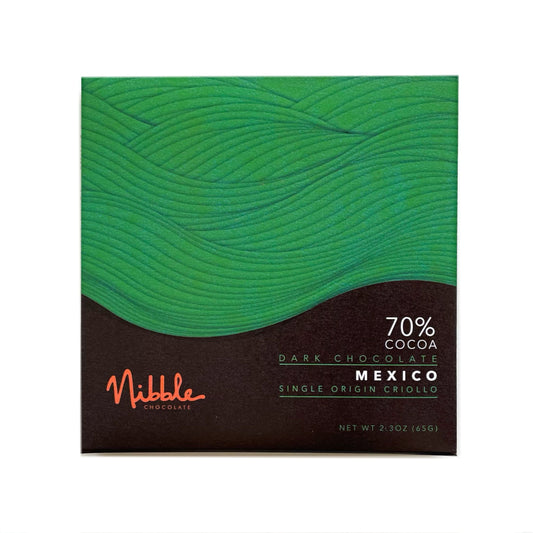

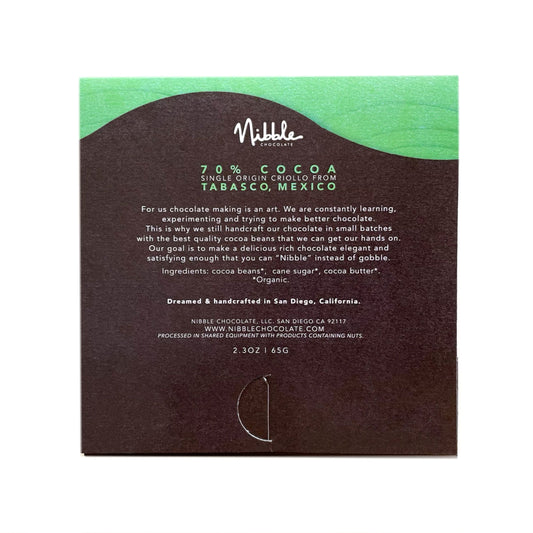

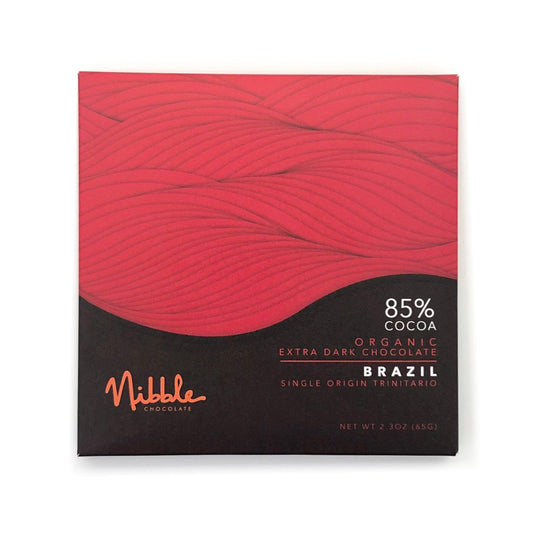

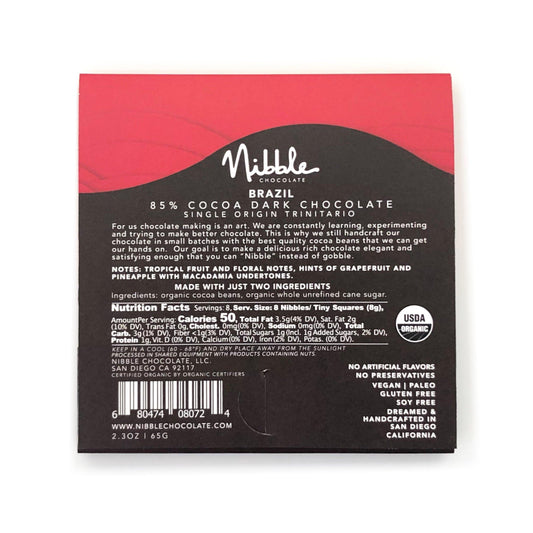

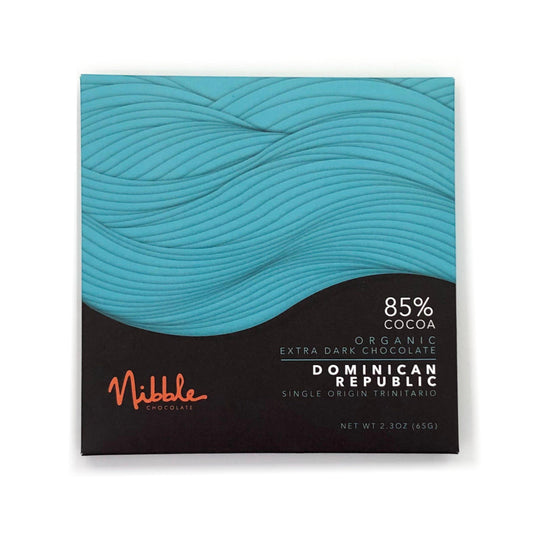

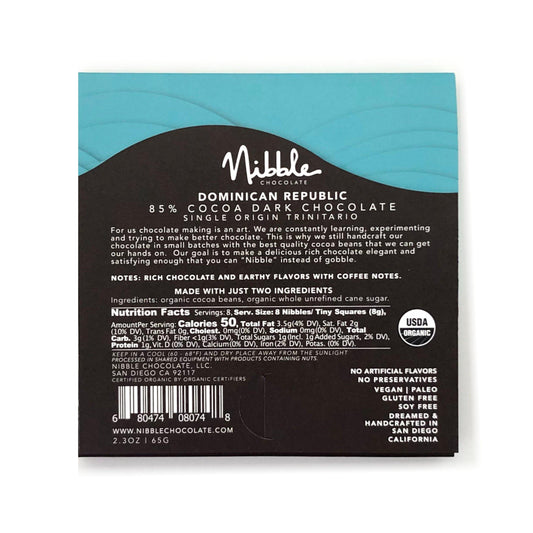

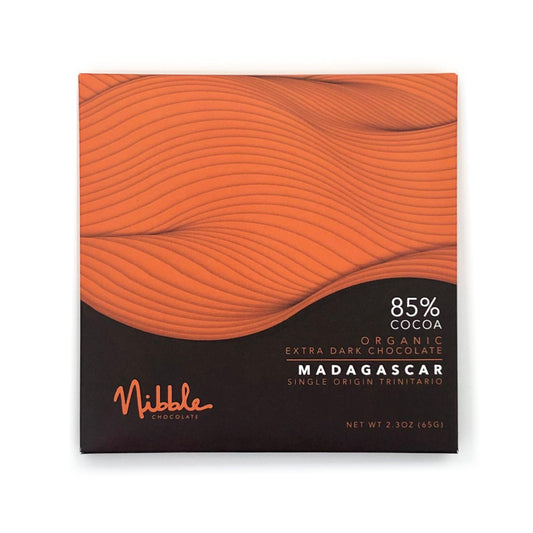

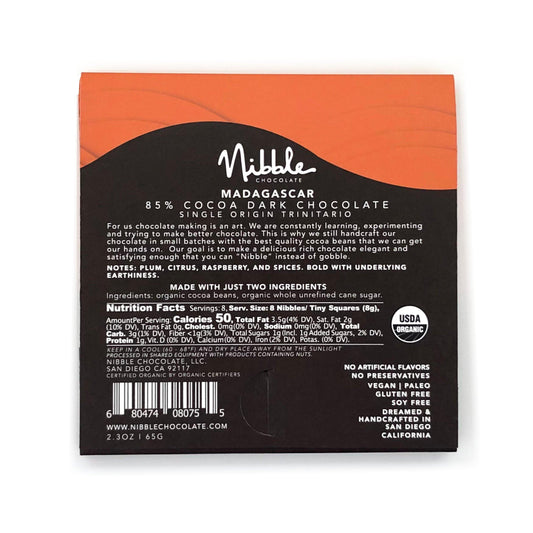

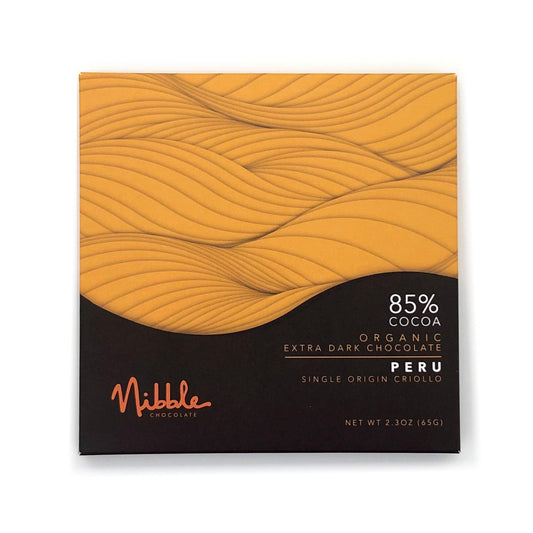

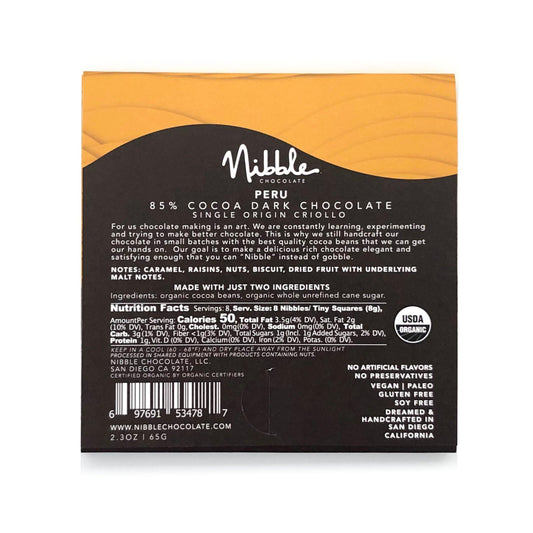

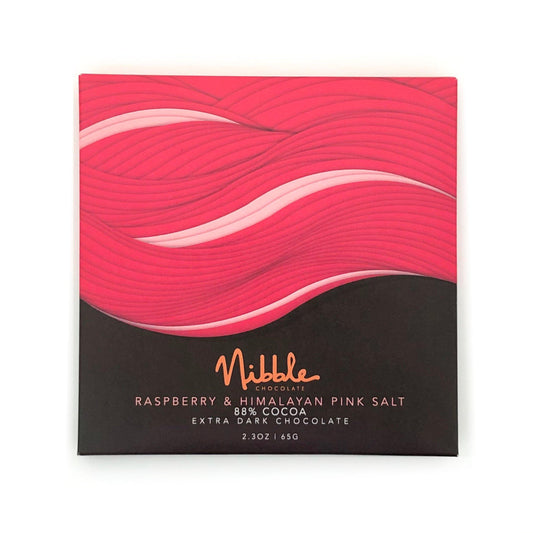

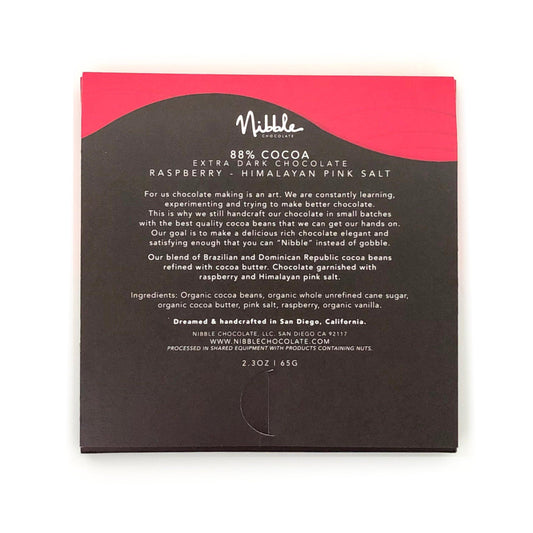

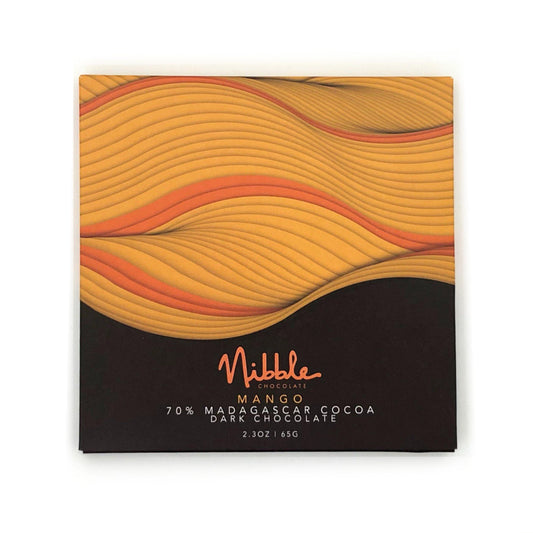

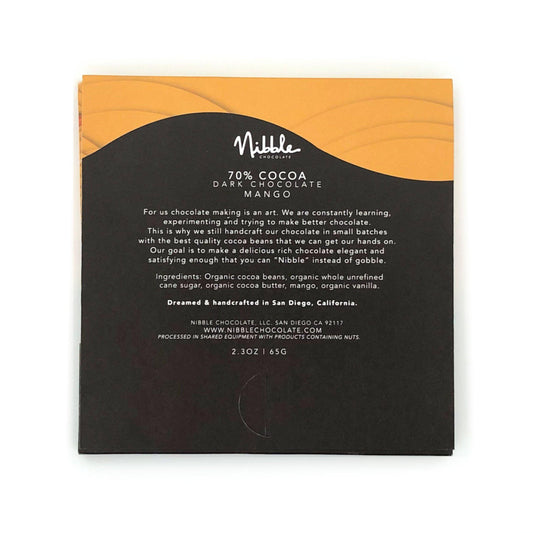

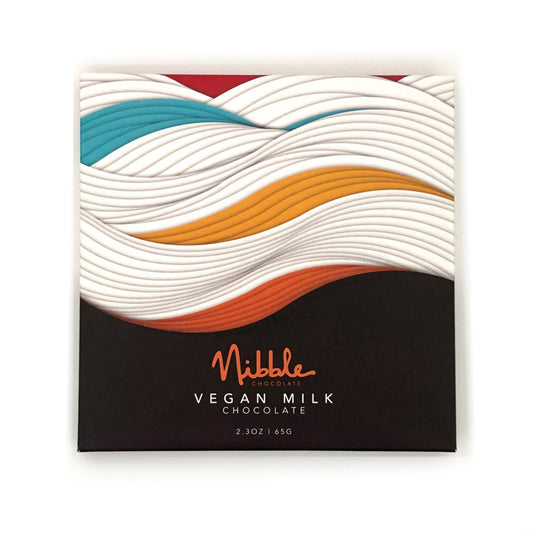

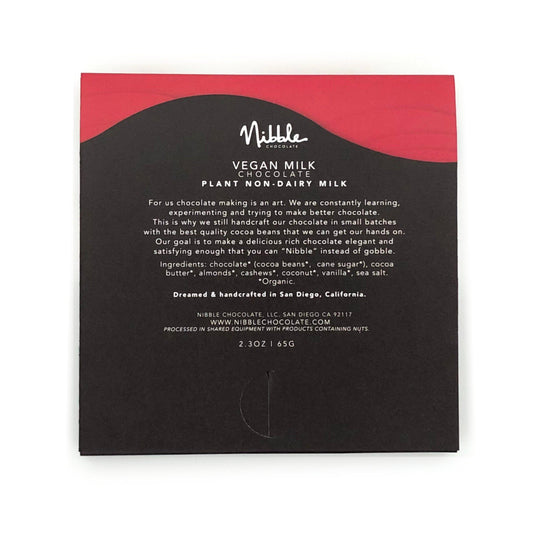

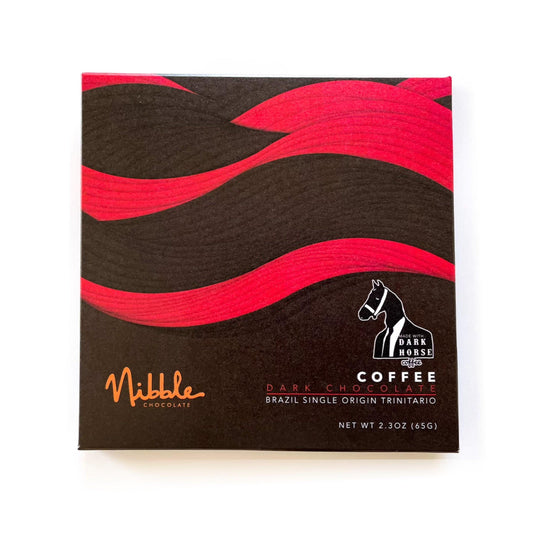

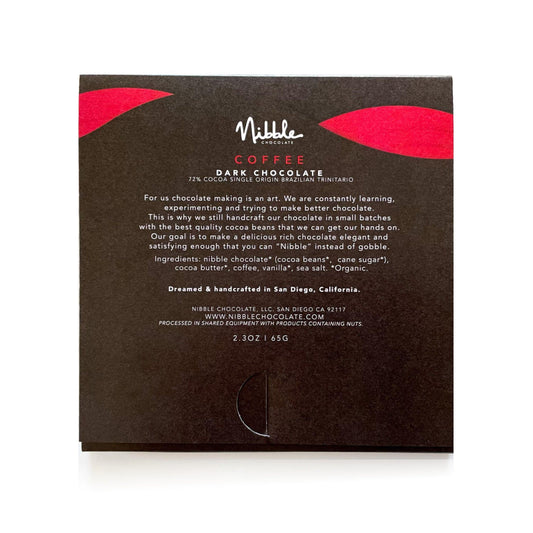

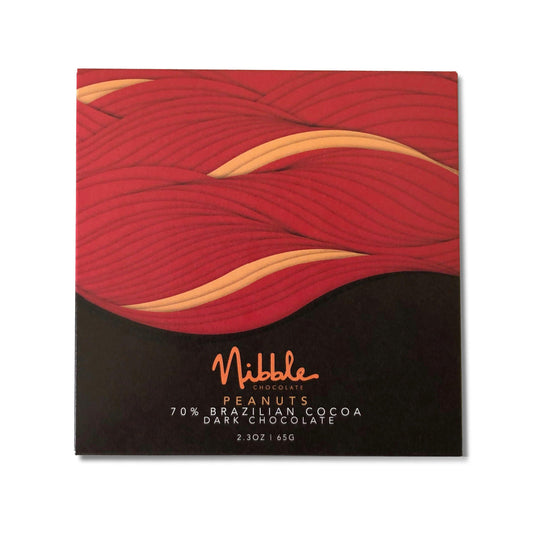

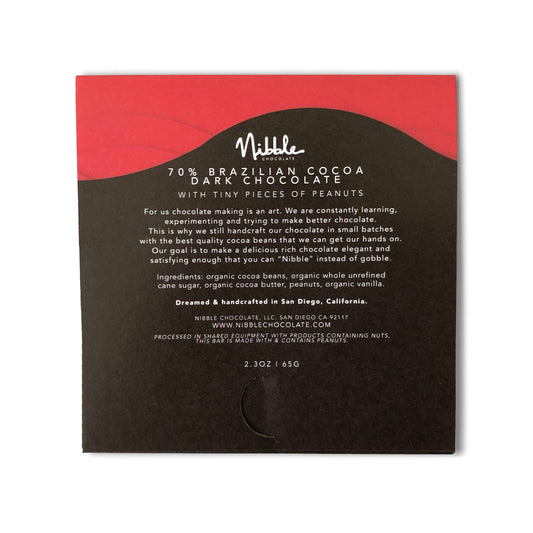

CHOCOLATE BARS

A Journey of Distinctive Flavors in Every Square

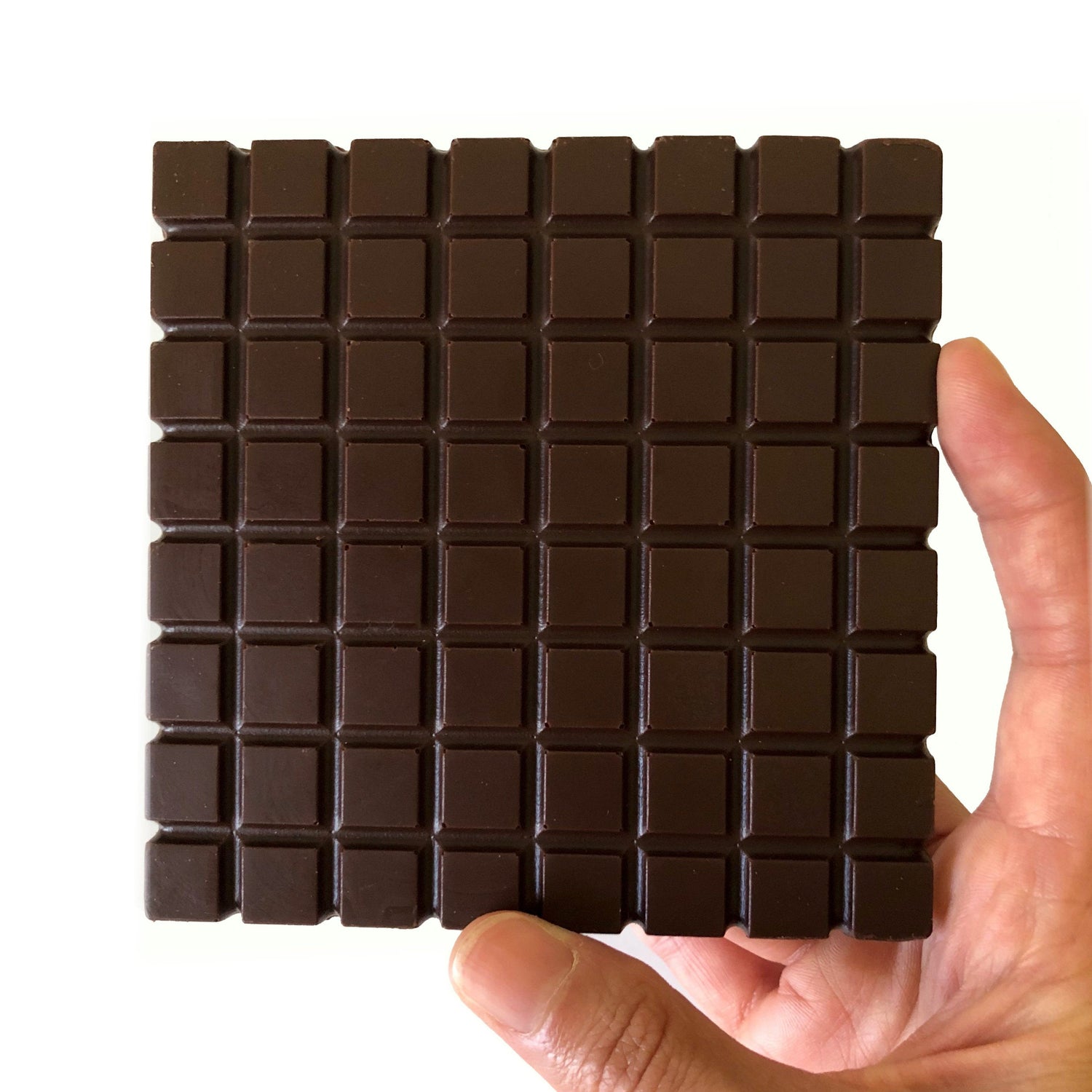

Bar weight: 2.3oz (65g)

Bar size: 4.3" x 4.3" x 0.20" (Inches)

Total Nibbles: 64

Nibble size: 0.4" x 0.4" x 0.20" (Inches)

+ Certified Organic

+ Whole Unrefined Cane Sugar

+ Vegan

+ Soy Free

+ Gluten Free

+ Paleo

single origin

-

72% Cocoa Brazil | Organic Dark Chocolate | Nibble Chocolate

Regular price $7.00Regular priceUnit price / per -

72% Cocoa Dominica Rep | Organic Dark Chocolate | Nibble Chocolate

Regular price $7.00Regular priceUnit price / per -

72% Cocoa Madagascar | Organic Extra Dark Chocolate | Nibble Chocolate

Regular price $7.00Regular priceUnit price / per -

72% Cocoa Peru | Organic Dark Chocolate | Nibble Chocolate

Regular price $7.00Regular priceUnit price / per -

70% Cocoa Mexico | Organic Dark Chocolate | Nibble Chocolate

Regular price $7.00Regular priceUnit price / per

-

85% Cocoa Brazil | Organic Extra Dark Chocolate | Nibble Chocolate

Regular price $7.00Regular priceUnit price / per -

85% Cocoa Dominican Republic | Organic Extra Dark Chocolate | Nibble Chocolate

Regular price $7.00Regular priceUnit price / per -

85% Cocoa Madagascar | Organic Extra Dark Chocolate | Nibble Chocolate

Regular price $7.00Regular priceUnit price / per -

85% Cocoa Peru | Organic Extra Dark Chocolate | Nibble Chocolate

Regular price $7.00Regular priceUnit price / per$0.00Sale price $7.00

inclusions

-

88% Cocoa Raspberry & Himalayan Pink Salt | Organic Extra Dark Chocolate | Nibble Chocolate

Regular price $7.00Regular priceUnit price / per -

70% Cocoa Madagascar Mango Infused | Nibble Chocolate

Regular price $7.00Regular priceUnit price / per -

Strawberry Cream Oat Milk | Non-Dairy Milk

Regular price $7.00Regular priceUnit price / per -

Vegan Milk | Non-Dairy Milk | Nibble Chocolate

Regular price $7.00Regular priceUnit price / per -

72% Cocoa Brazil Coffee Infused | Nibble Chocolate

Regular price $7.00Regular priceUnit price / per

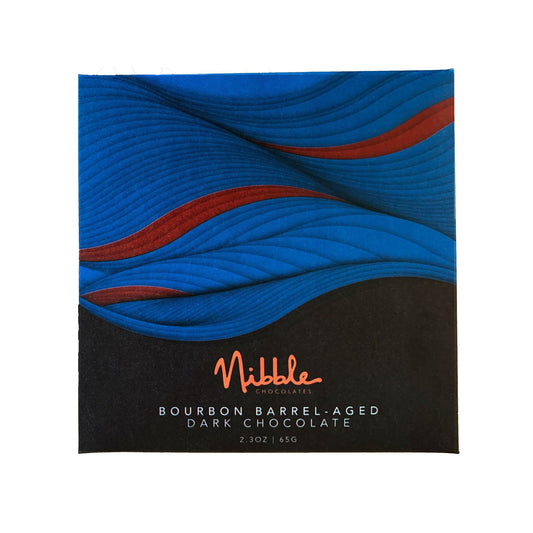

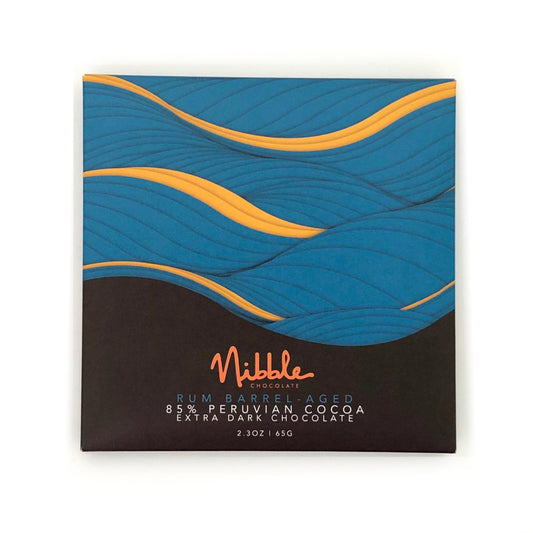

limited edition

-

Bourbon Infused Barrel-Aged Chocolate | Nibble Chocolate

Regular price $18.00Regular priceUnit price / per -

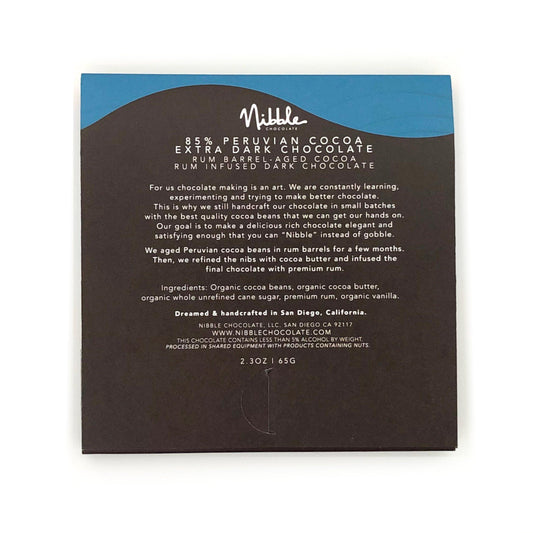

Rum Infused Barrel-Aged Chocolate | Nibble Chocolate

Regular price $18.00Regular priceUnit price / per -

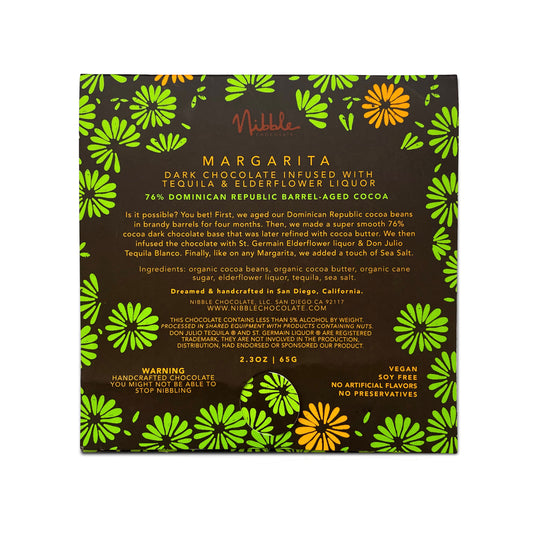

Margarita Chocolate Bar | Infused with Tequila & Elderflower Liquor

Regular price $16.00Regular priceUnit price / per -

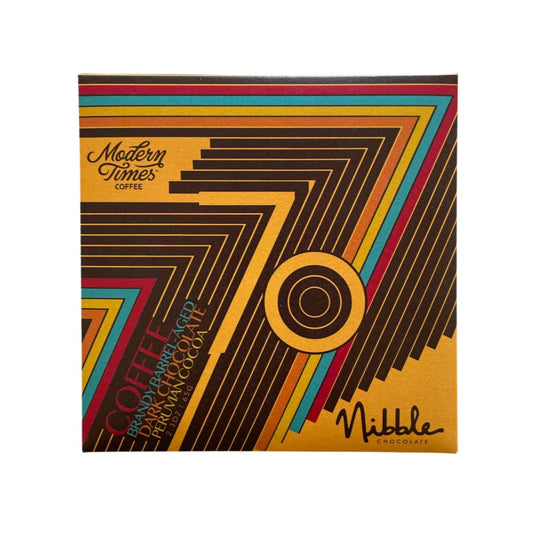

Brandy Barrel-Aged Cocoa and Coffee | Nibble Chocolate

Regular price $14.00Regular priceUnit price / per -

70% Cocoa Brazil & Peanuts | Nibble Chocolate

Regular price $7.00Regular priceUnit price / per

POWDERED CHOCOLATE

Unleash Your Inner Barista! Simply blend, Sip, and Enjoy

Transform your kitchen into a cozy café with our premium powdered chocolate. Whether you're craving the rich allure of a Mocha or the classic comfort of Hot or Iced Chocolate, the power to create your favorite indulgence is in your hands.

+ Certified Organic

+ Whole Unrefined Cane Sugar

+ Vegan

+ Soy Free

+ Gluten Free

+ Paleo

-

Hot Chocolate | Powdered Chocolate Brazil | Nibble Chocolate

Regular price $15.00Regular priceUnit price / per -

Hot Chocolate | Powdered Chocolate Dominican Republic | Nibble Chocolate

Regular price $15.00Regular priceUnit price / per -

Hot Chocolate | Powdered Chocolate Madagascar | Nibble Chocolate

Regular price $15.00Regular priceUnit price / per -

Hot Cocoa Chocolate Peru - Nibble Chocolate

Regular price $15.00Regular priceUnit price / per

Thank You!

Thank you for exploring and discovering our small-batch chocolate.

We take pride in our commitment to certified organic, vegan, dairy-free, fair trade, and sustainable practices, ensuring each bite is a conscious delight. With no artificial sweeteners, colors, flavors, or preservatives, and free of soy, our chocolates offer a full-bodied experience of pure indulgence.

We invite you to experience the richness of our chocolates and join us in our journey towards a more sustainable and delicious future!